Products

0086-379-63939358

Brown Fused Alumina is produced by fusion of calcined bauxite in an electric arc furnace at over 2000 centigrade.It stands out due to very high toughness so that it has a long lifespan but cool cutting is not expected.By these characters,it widely use for working on regular steel,carbon steel,forging steel,ingot steel and cast iron,malleable iron as well as some non-ferrous metals.

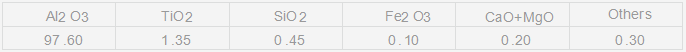

Chemical composition%(Grit 36)

Particle size distribution

F8–F1200 are available,PSD according to FEPA standard 42,GB/T 2481.

JIS standard or ANSI standard or customer’s specific required is also available.

Bulk Density(g/cm3)

Bulk Density is a typical index to express the shape different.

RUNBAO divide regular brown by different grains shape in two types AF10 and AF20.AF10 has blocky shape with high impact resistance and AF20 has angular shape with sharp cutting edge.So that AF10 has higher toughness and AF20 has higher cutting quality.

Medium shapes(Bulk density between AF10 and AF20)are also available under customer special requirements.

Semi-friable Fused Alumina is produced by fusion of very special bauxite and Bayer-alumina with additive minerals in an electric arc furnace,The pure alumina content give higher hardness crystal compare with regular brown and the additive minerals content give higher toughness compare with white and pink.So that ASF is endued excellent cutting performance with durable tool life.

Chemical composition%(Grit 46)

Particle size distribution

F8–F1200 are available,PSD according to FEPA standard 42,GB/T 2481.

JIS standard or ANSI standard or customer’s specific required is also available.

Bulk Density(g/cm3)

Blocky shape and sharp shape are also available under customer special requirements.

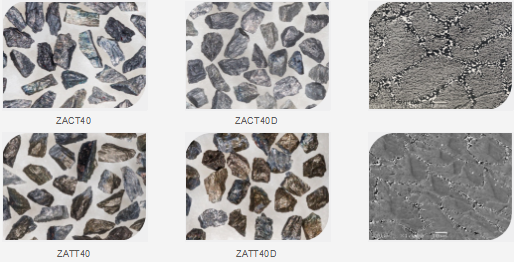

Zirconia Alumina is abrasive eutectic alloy of alumina and zirconia which produced by fused alumina and zirconia at 2900 centigrade.By specially controlling the fusion formula and cooling,it creates very fine micro crystal fracture properties which impact Zirconia Alumina remarkable cutting ability and rapid stock removal rate.With different working materials,Zirconia Alumina bring several times longer life compare with ordinary abrasives.Zirconia Alumina mostly use in stainless steel,high alloy steels and other low thermal releasing grinding system.

By fusion inside different quantity Titanium,we can obtain different tough-sharp balance.

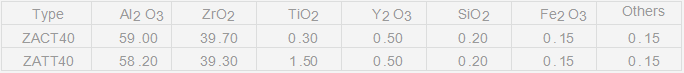

Chemical composition%(Grit 46)

Particle size distribution

F8–F220 are available,PSD according to FEPA standard 42,GB/T 2481.

JIS standard or ANSI standard or customer’s specific required is also available.

ZAF25 is the most dense and tough abrasive grains which produced by fused alumina and zirconia at 2900 centigrade.With the Alumina-Zirconia eutectic crystalline structure,ZAF25 has extremely high wear resistance which impact the abrasive remarkable tool life.ZAF25 mostly use in foundry-type grinding wheels and steel conditioning wheels.

ZAF25D has more blocky shape than ZAF25.

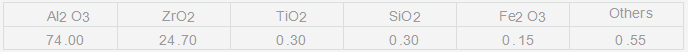

Chemical composition%(Grit 20)

Particle size distribution

F8–F220 are available,PSD according to FEPA standard 42,GB/T 2481.

JIS standard or ANSI standard or customer’s specific required is also available.

For purpose of improve fracture resistance of grains,regular brown fused alumina can be calcined at 1050 centigrade.At this temperature the grains internal micro-crack could be recovered and internal stress could be released as well as the hydrophily improved,so that the grains toughness increased and then the wheel become more long lasting tool life.

We symbol this treatment as“C1050”.

For purpose of high stress working conditions,regular brown fused alumina can be heat treated at 1350 centigrade(open annealed),thereafter the color change from brown to blue.This treatment could renovate most of crystal imperfection and modify the crystal lattice with foreign oxides.Then the grains are impacted both higher tool life and cutting quality.

We symbol this treatment as“HT”.