Products

0086-379-63939358

For purpose of improve the bonding behavior of grains,WAF could be modified the surface by ceramic coating.Thereafter,the coating will create a ligament between grains and resin.Meantime,the heat treated during process could also modify the crystal to increase the toughness of the grains.

As result,the tool life can be remarkable improved.

We symbol this product as“WACC”.

Regular ceramic coating of WACC adopt Fe2 O3 as the major layer.But in some application required iron free or color free,it could apply this white ceramic coating,the coating layer is totally iron free and white color.The performance can nearly catch up regular WACC.

We symbol this product as“WAZ”.

In some high quality required application,special high quality WA is expected.Then we can selected only the perfect pure crystal ingot from furnace specific position.In addition to this,we do special heat treated to the grains.Then the best quality WA stand out from whole WA series.

We symbol this product as“SWA”.

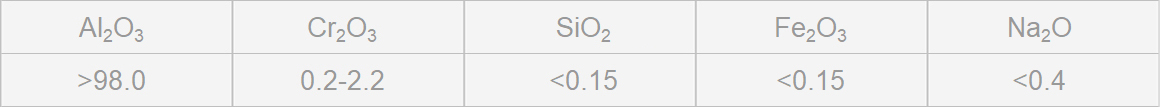

Pink fused alumina is produced by fusion of Bayer-alumina with additive Chromium oxide in an electric arc furnace at over 2100 centigrade. The Chromium oxide impact a bit higher toughness than White fused alumina. Due to different Chromium content, we separately provide 3 types of Light pink, Pink and Ruby. Along with chromium oxide content increased, the color become more and more dark and the grains become more and more tough.

Green SiC is produced by the reaction of quartz sand and a carbon carrier with additive salts in the electric resistance furnace. The GCF10 are carefully selected the most compact crystal structure Sic roll near the core. After perfect acid treatment and water washing after crushing, the free carbon content and iron content of grains are reduced to minimum then the shining pure green color crystal is imparted. GCF10 has blocky grains shape with very sharp cutting edges, could apply to grinding wheel and honing stone for working on plastic, stone, ceramic, glass and nonferrous metals.

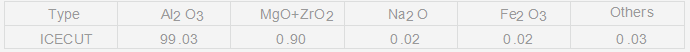

ICECUT is an advance abrasive material produced by sol gel technology with special boehmite and seeds.The nano crystal structure offer the grains extremely micro fracture when stressed.

With uneaqualed self-sharpening property,the tools offer long-lasting cool cutting life with extremely sharpness.It is worthy of the name of ideal abrasive grains in today and future.

Chemical composition%(Grit 46)

Particle size distribution

F8–F1200 are available,PSD according to FEPA standard 42,GB/T 2481.

JIS standard or ANSI standard or customer’s specific required is also available.

Bulk Density(g/cm3)

Blocky shape and sharp shape are also available under customer special requirements.